We Service Internationally!

Take Materials Production In-House with A Ball Mill Grinder

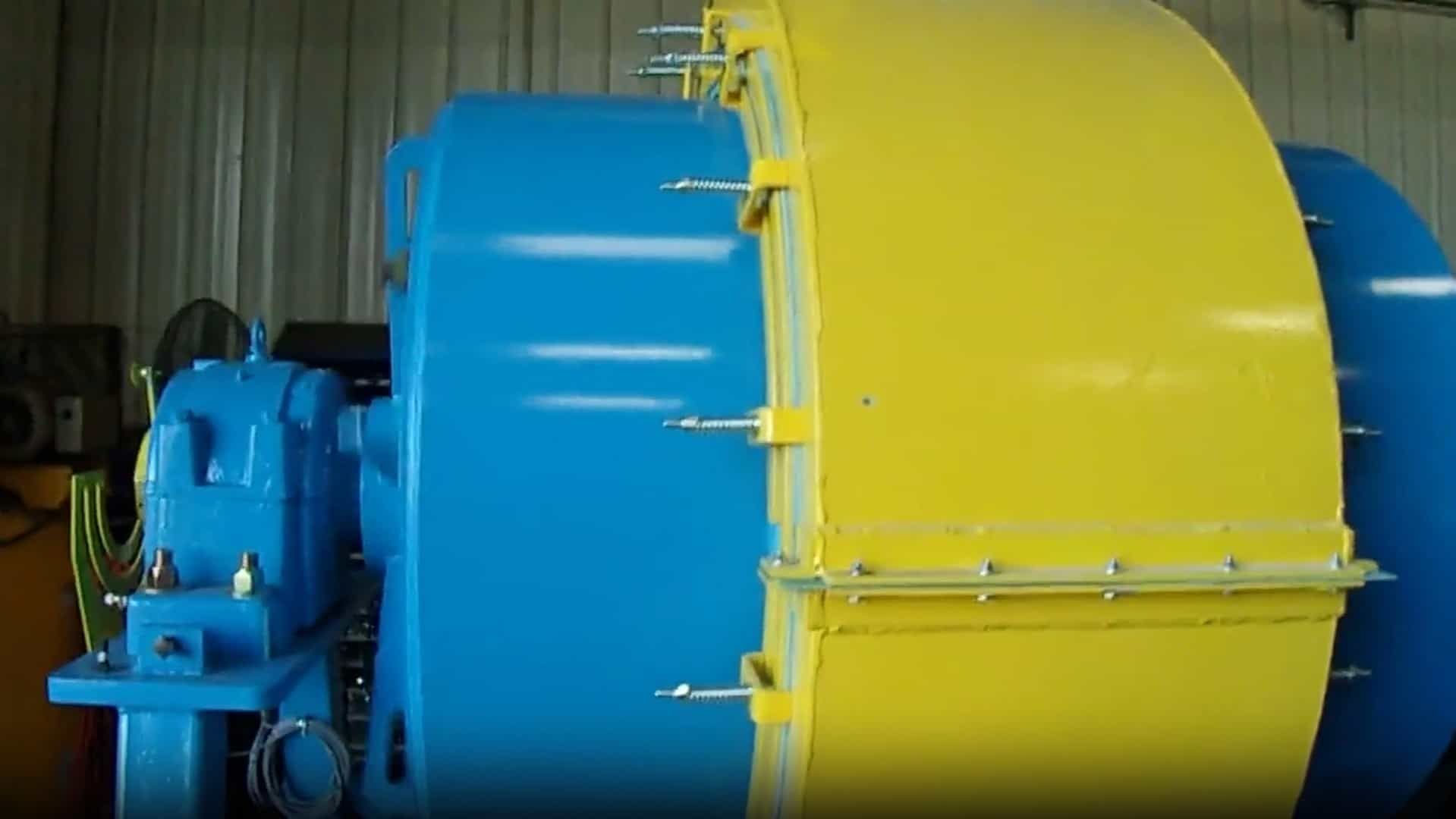

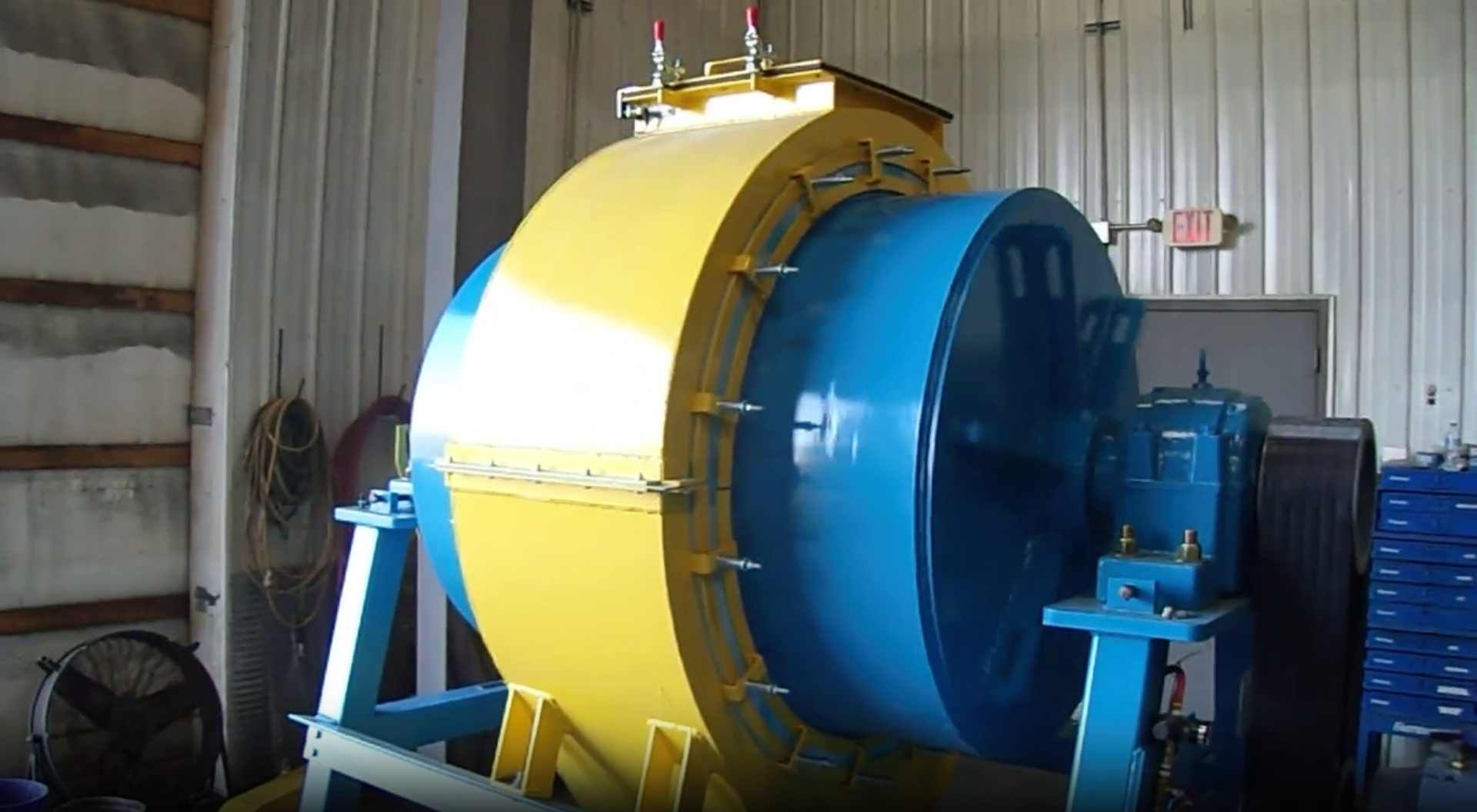

As manufacturing businesses, you must navigate a competitive global landscape, and a key strategy for success is increasing your operational efficiency. By bringing various parts of the manufacturing processes in-house, such as mill grinding, your company can save substantial time and money in the overall production process. One of the most effective ways to facilitate production is with the use of a ball mill grinder.

Economy Ball Mill is an original equipment manufacturer (OEM) located in Tollesboro, Kentucky. We have been helping businesses worldwide implement an in-housing strategy when it comes to material reduction. Offering the highest quality custom ball mill grinders and attritor mill barrel rebuilds, we are helping businesses and manufacturers put the control of materials production directly back into their hands instead out outsourcing this production to a third-party partner.

Before we delve into how a ball mill grinder can revamp your entire production process, let's explore the basics of the ball mill grinding process in both its forms: wet and dry.

Wet and Dry Ball Mill Grinding

The principles of mill grinding apply to both wet and dry processes, but each come with their own advantages and limitations.

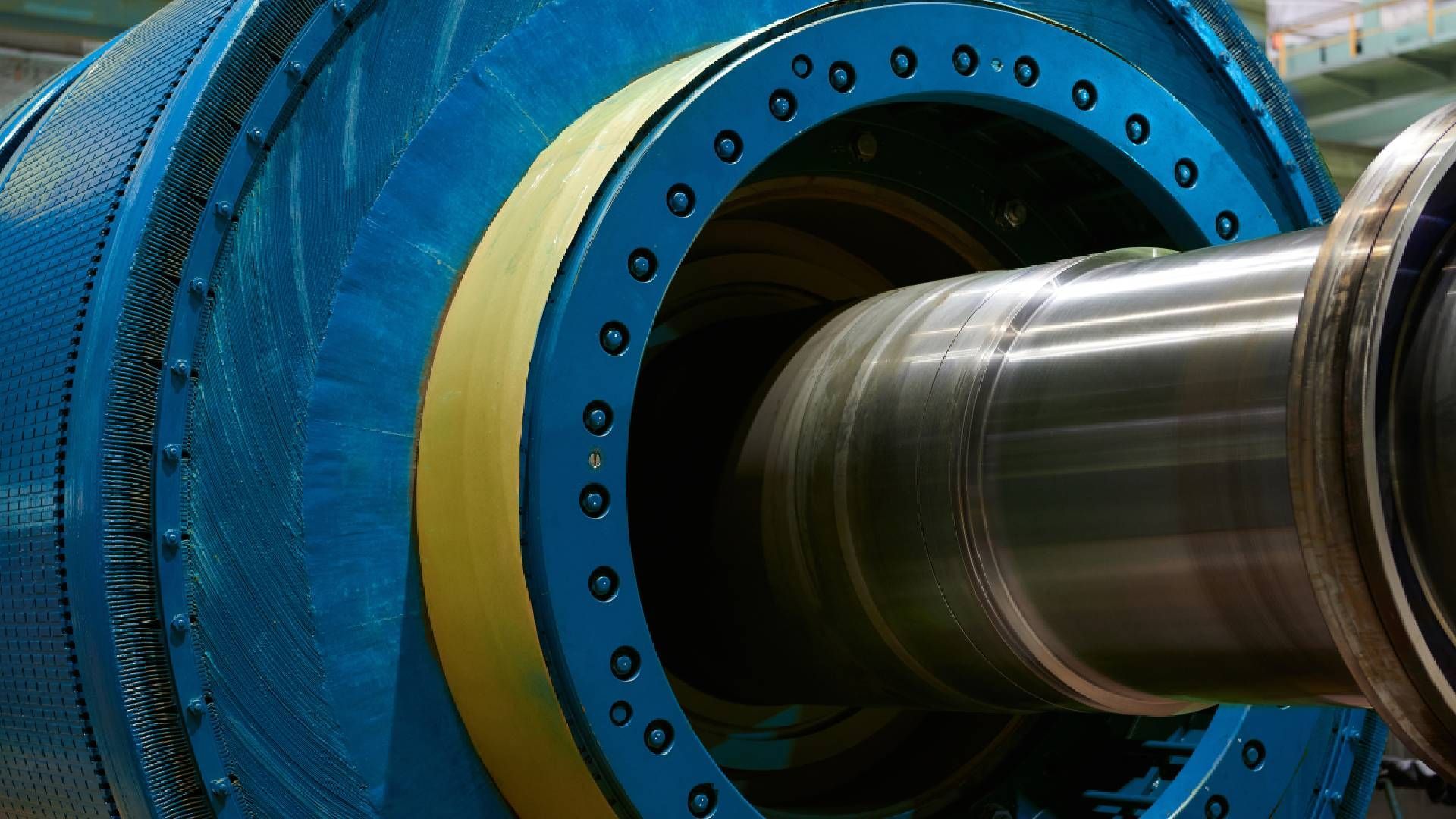

Wet Ball Mill Grinding: The wet mill grinding process involves a ball mill that works with a liquid medium such as water or an oil-based product which aids in the grinding process. The fluid medium helps to reduce friction, enhances particle size reduction, and ensures more homogeneous particle reduction. However, this method comes with the need for additional equipment and time for drying and processing that resulting media.

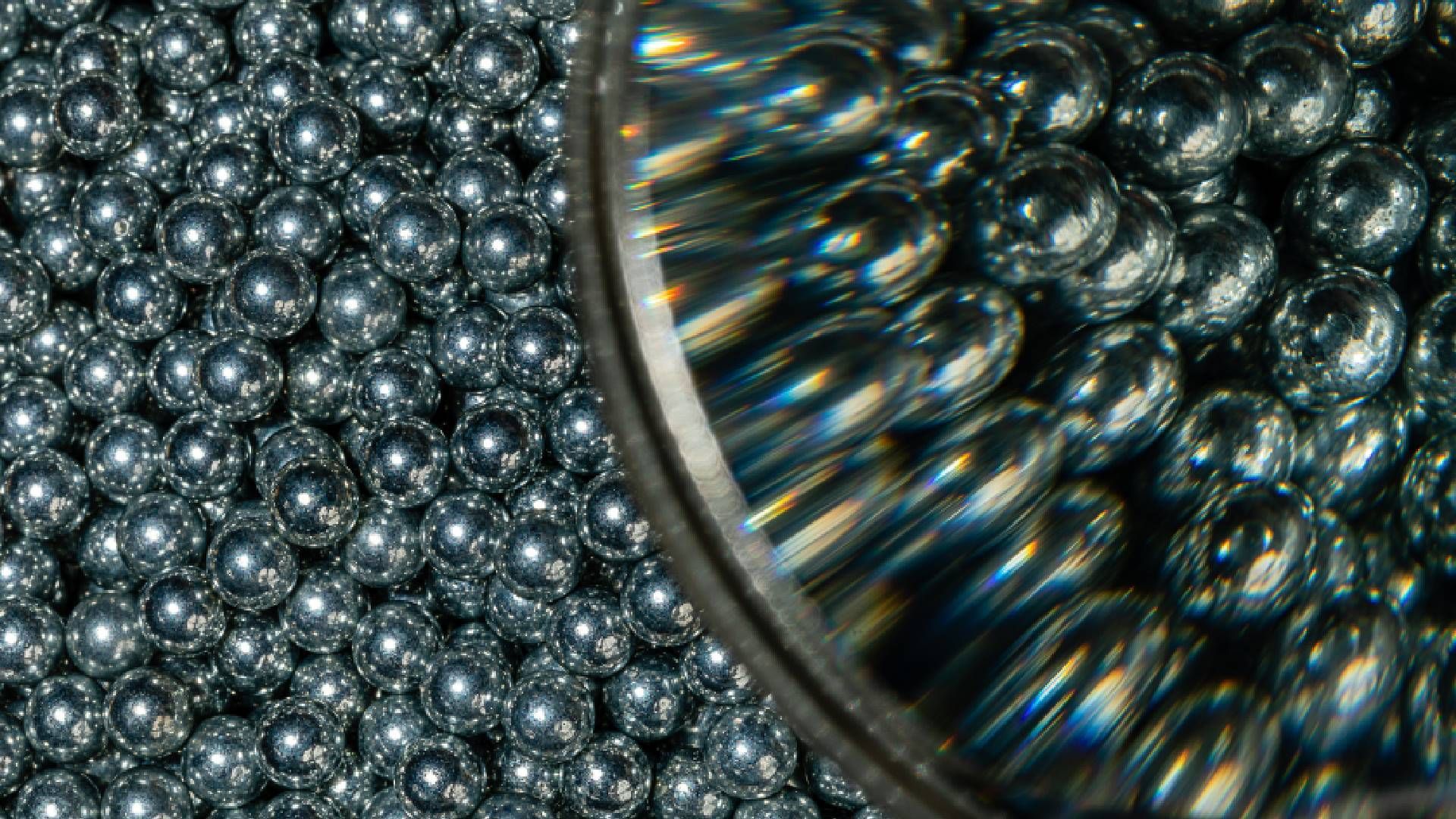

Dry Ball Mill Grinding: In contrast, dry grinding processes rely on the kinetic energy of a grinding medium like steel or ceramic balls. The friction between the grinding media and the product creates a reduction in size without the use of a liquid medium. Due to the lack of liquid, dry grinding can lead to increased dust and the potential for static charges. However, the simplicity and cost-effectiveness of the process make it a popular choice for many industries.

Custom Ball Mill Grinders: An Investment Worth Making

Given the versatility and numerous advantages of an investment in a custom ball mill, making this strategic decision can steer a business towards further growth. Here are a few reasons why it makes sense to begin investing in a ball mill grinder:

- Increased Efficiency: Ball mill grinders offer enhanced grinding efficiency compared to other material reduction methods. Depending on the requirements of the material you’re processing, we can customize a ball mill to grind materials to the smallest of sizes, facilitating your in-house control of the entire production process.

- Cost Savings: Having a ball mill grinder on-site eliminates the need for outsourced grinding work to a third-party, reducing costs significantly. This means your materials don't need to leave your facility, minimizing transport and production costs and eliminating the risk of extended manufactory and delivery times.

- Quality Control: When you grind your own materials, you get to define the quality standards of your material attrition. Optimize product quality and consistency with set parameter controls, enabling you to reduce waste.

- Versatility: Ball mills are versatile. Depending on your needs, they can handle various materials: metals, ceramics, organic materials, and more. Whether milling for chemical, pharmaceutical, food processing, or mineral industries, a ball mill grinder delivers consistent, reliable results.

Contact Us To Customize Your Ball Mill Grinder

In an increasingly competitive business environment, the ability to streamline your manufacturing processes, save on transportation costs, and maintain high quality control is crucial to your business’s bottom line. A custom ball mill grinder from Economy Ball Mill offers a realistic and cost-effective solution for material reduction, especially for businesses looking to bring their production process in-house.

If you're interested in learning more about our custom ball mills, contact our team at Economy Ball Mill or give us a call at 1-606-798-5724.

Serving companies worldwide from our headquarters in Tollesboro, Kentucky with our industry expertise and dedication to customer satisfaction, Economy Ball Mill stands ready to help your business turn production challenges into opportunities for growth.

All Rights Reserved | JSB Industrial Solutions, INC