Using a Ball Mill to Create Limestone Powder

Limestone is a versatile resource used in various industries. When ground into a fine powder, it becomes even more valuable for all sorts of purposes like construction, agriculture, water treatment, healthcare, and beyond.

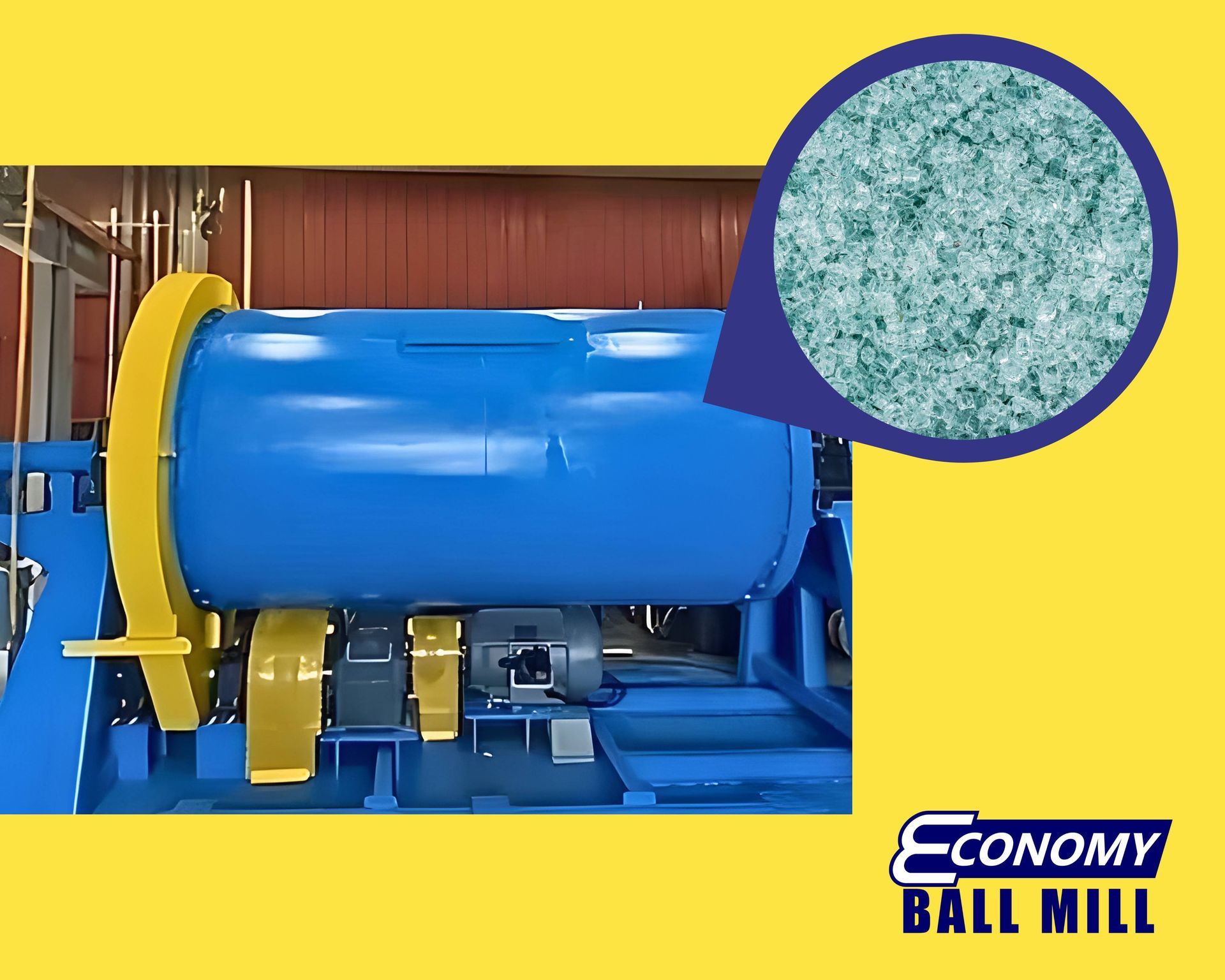

At Economy Ball Mill, we can help your business save time and money in processing limestone rocks into limestone powder with the help of a custom ball mill. Keep your material processing in house with an efficient tool that you can design to meet the needs of your business!

In this blog post, we'll explore the purposes of powdered limestone and how to use a custom ball mill to create it efficiently.

The Many Purposes of Powdered Limestone

Limestone powder, also known as ground limestone, has numerous applications across different sectors:

- Agriculture: Farmers use powdered limestone to neutralize soil acidity, to improve crop yields, and as filler for feed to promote bone growth, as it is high in calcium.

- Construction: It's a key ingredient in cement and concrete production.

- Paint Industry: It serves as a pigment and extender in various types of paint.

- Water Treatment: Limestone powder helps adjust pH levels in water treatment facilities.

- Pharmaceuticals: It's used as a calcium supplement and also as an ingredient for antacids.

Benefits of Using a Ball Mill for Limestone Powder Production

Ball mills offer several advantages for creating limestone powder. You can achieve a consistent particle size distribution, including a very fine powder down to 5 microns or less with the correct grinding media and run time. This process is also as scalable as you would like it to be, and your ball mills can be run together in batches or in a cascading effect to complete continuous operation for high-volume production. Versatile in handling different types and hardnesses of materials, including limestone rocks and many other types of aggregate and other materials, custom ball mills have easily replaceable linings and parts and offer low maintenance requirements compared to other types of material processing equipment.

Using a Ball Mill to Create Limestone Powder in a Batch Process that is for Dry Materials

A ball mill is an excellent choice for grinding limestone into a fine powder. Here's how to use one effectively:

- Load the ball mill: Fill your ball mill cylinder to the appropriate point with crushed limestone. Add grinding media (like stainless steel balls) to occupy roughly 20% of the drum's volume.

- Set the rotation speed: Adjust the mill's speed to achieve the optimal grinding action.

- Start the milling process: Allow your ball mill to run. The rotating drum causes the grinding media to cascade, crushing and grinding the limestone into progressively finer particles. Check the powder periodically to assess its fineness. Adjust the milling time as needed to achieve your desired particle size.

- Discharge and sieve: Once your desired fineness is reached, stop the mill and discharge the powder. Use a sieve to ensure consistent particle size and separate any larger particles for regrinding.

- Quality control: Test the limestone particulates to ensure it meets your required specifications for its intended use.

Learn More Aggregate Processing Solutions At Economy Ball Mill

By using a ball mill to create limestone powder, you can ensure a consistent, high-quality product that meets the demands of various industries. Whether you're in agriculture, construction, or any other field that requires finely ground limestone, a well-designed ball mill is an invaluable tool in your production process.

At Economy Ball Mill, we specialize in manufacturing custom ball mills designed to meet your specific production needs. Our expert team can help you select the right size, design, and custom features to optimize your materials grinding process so that you can produce high-quality results like powdered limestone efficiently.

Contact us online or give us a call at (606) 798-5724 to learn more about our custom ball mills. We serve clients across the United States and internationally from our site in Tollesboro, Kentucky.