Pumice & Slag Grinding Alternatives to Fly Ash

The construction industry is evolving, and with fly ash supplies dwindling due to reduced anthracite coal production, manufacturers need reliable alternatives when it comes to the production of cement byproducts that need reduced by grinding.

Pumice and slag—both abundant and sustainable—are stepping up as viable replacements.

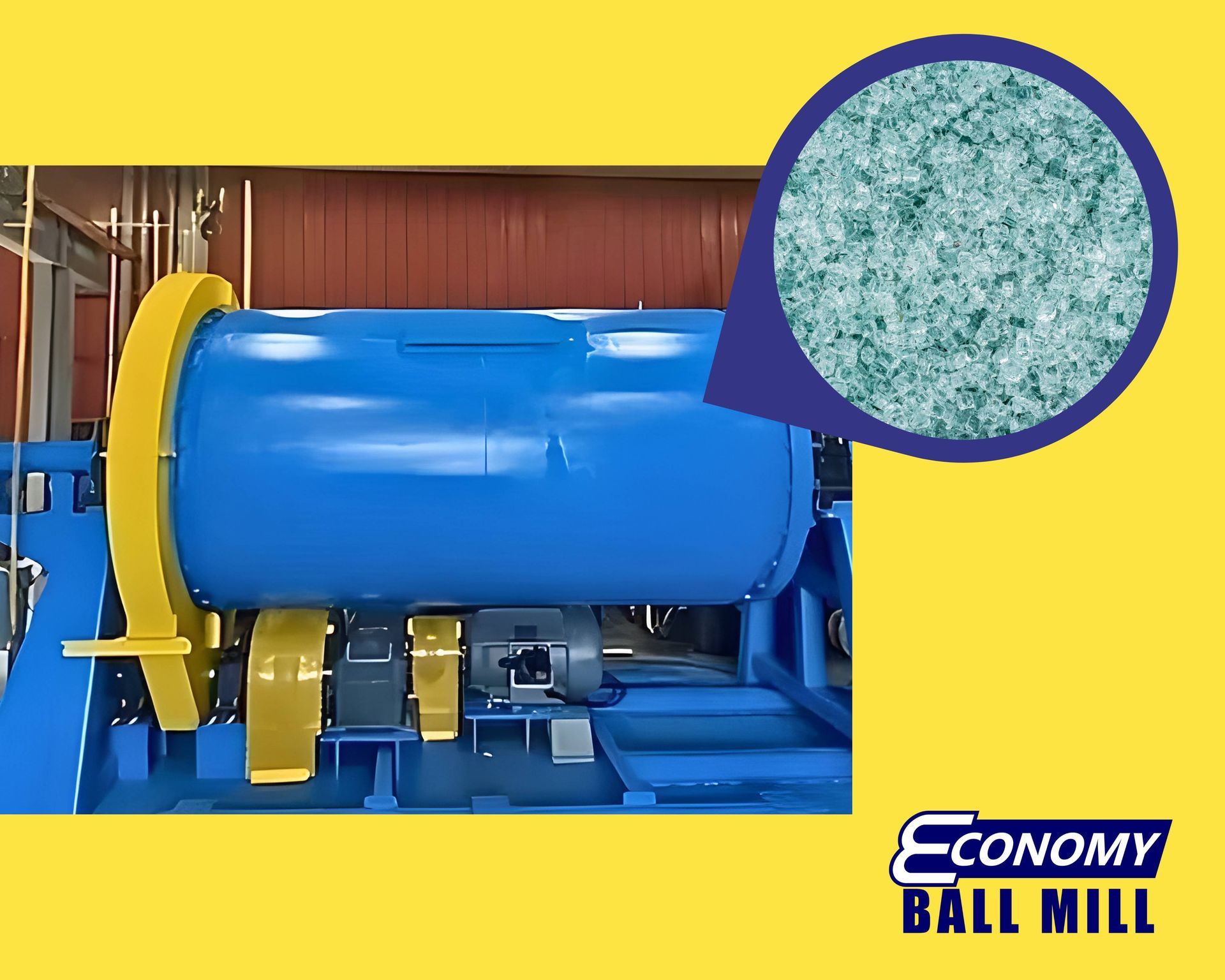

At Economy Ball Mill, custom-engineer ball mills for precision grinding, whether you’re processing pumice for lightweight concrete or slag for cement enhancement. Our clients return to us for ball milling solutions because they need equipment that works—no compromises.

Why Pumice & Slag Are Gaining Traction

Fly ash has long been a staple in cement grinding, but with stricter environmental regulations and the decline of coal-fired plants, alternatives are essential. Both pumice and slag offer unique advantages:

- Natural Pozzolanic Properties: Like fly ash, when combined, pumice and slag react with lime to create stronger, breathable, and sustainable concrete and plasters.

- Abundant & Sustainable: Pumice is mined from volcanic deposits, while slag is a byproduct of steel production. No reliance on coal.

- Improved Durability: Enhances resistance to moisture infiltration and damage from a freeze-thaw cycle.

- Lightweight Option – Pumice reduces concrete weight without sacrificing strength.

The Role of Ball Mills in Processing Pumice & Slag

Grinding these materials to the right consistency is critical. Too coarse, and they won’t react properly. Too fine, and you waste energy. Our custom ball mills ensure optimal particle size distribution for maximum performance.

Key Adjustments for Efficient Grinding

- Variable Rotational Speed: Different hardness levels in pumice and slag require tailored grinding intensity.

- Adjustable Media Size: Steel, ceramic, or alumina grinding balls prevent contamination.

- Dust Control: Closed-circuit systems with air classifiers minimize airborne particles.

- Wet or Dry Processing:Some applications benefit from wet grinding in a slurry; others need dry milling. Our experts can help you choose the best option for you.

Surface Mining Pros: Sourcing Raw Material Efficiently

Pumice and slag are surface mined, often as a byproduct of other material processing, which offers several advantages:

- Lower Operational Costs: No need for extensive underground mining infrastructure.

- Easier Extraction: Open-pit methods allow for high-volume production and sale.

Why Our Ball Mills Stand Out

We don’t offer off-the-shelf solutions when it comes to creating a custom ball mill. Our customers know exactly what they need, and we deliver:

- Custom-Engineered for Your Process: Whether you’re grinding pumice for lightweight concrete or slag for cement additives, we optimize the mill for your material.

- Built for Efficiency: Adjustable parameters ensure minimal energy waste and maximum output.

- Durable & Low-Maintenance: Designed for continuous operation in demanding environments.

We even perform product development and testing for our clients. Our in-house materials testing service is one way that we can help businesses plan with accurate predictive modeling for best grinding performance.

Our tester horizontal ball mill (20"x28") replicates most full-scale ball mill operations, requiring just 10 gallons of material for testing at our in-house facility. Whether you’re processing fly ash, pumice, slag, or complex compounds, we deliver transparent insights into how your material will behave in production.

Transitioning from Fly Ash? Let’s Talk Grinding Solutions

The shift away from fly ash isn’t slowing down. If you’re exploring pumice, slag, or other alternatives, the right grinding equipment is vital for your business.

Contact us online or call (606) 798-5724 to learn more about your next custom ball mill solution from Economy Ball Mill!

We serve clients around the world from our site in Tollesboro, Kentucky and look forward to working with you.