Achieve the Ideal Limestone Size with Wet Grinding Solutions

A competitive manufacturing or processing landscape, using a custom ball mill to create the perfect limestone powder for your industrial application is crucial for manufacturers across various sectors.

If you’ve been debating on whether dry ball mill grinding or wet grinding solutions would be the best for your enterprise, both options could provide an efficient and effective method for different means.

Depending on your goals, you can create high-quality limestone powder for use in multiple industries using wet grinding methods. Let's explore how wet ball mill grinding can revolutionize limestone processing and benefit your production process.

The Importance of Powder Limestone: Particle Size

Limestone is a versatile material used in numerous applications, but its effectiveness often depends on achieving the right particle size for its use.

Finer particles generally lead to better performance in most applications, because the finer the powder, the larger the surface area. This also means that finer powder limestone has improved reactivity compared to its coarser counterparts.

This is where wet grinding solutions come into play, allowing manufacturers to reduce limestone to the ideal size for their specific needs.

Advantages of Wet Grinding for Limestone Industry

While dry grinding is an excellent solution for limestone processing, wet grinding offers some key advantages over dry grinding methods, especially for fine powder applications:

- Better particle size control: Wet grinding allows for more precise control over particle size distribution, which means a more consistent end product.

- Reduced dust: The wet grinding process significantly reduces airborne dust, improving environmental conditions.

- Better heat management: Water allows for natural heat dissipation, reducing friction and abrasive wear.

- Improved product quality: Wet grinding often results in a more uniform particle size and shape for fine grinding.

Wet Ball Mill Grinding for Best Limestone Size

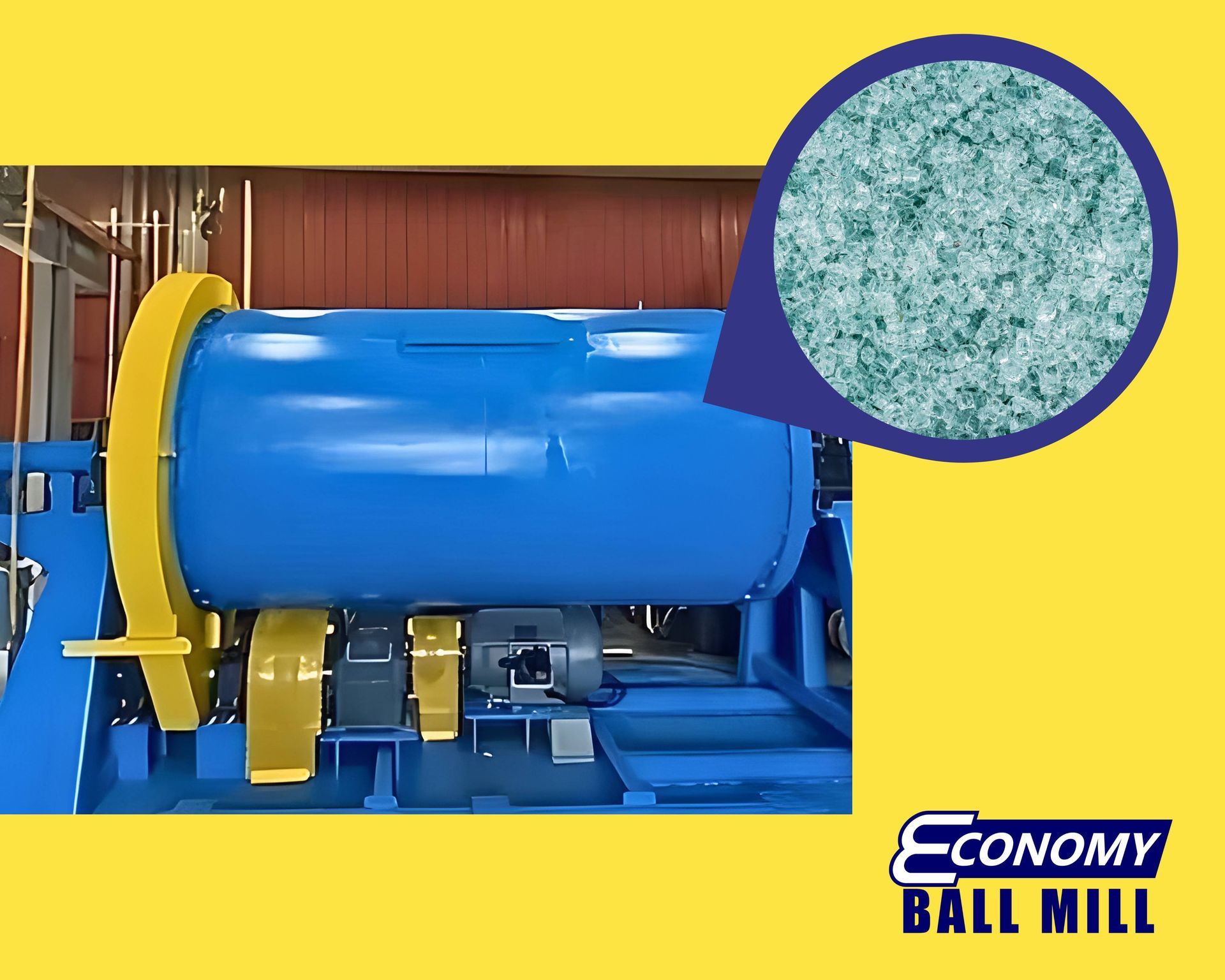

Economy Ball Mill's wet grinding solutions utilize a ball mill with a rotating cylinder filled with grinding media and a slurry of limestone material and a fluid medium like water. As the cylinder rotates, the grinding media cascades and crushing the limestone materials to the manufacturer’s desired size. When the target particle size is achieved, the slurry is discharged and separated. At this point, the wastewater needs to be disposed of properly.

Applications in Various Industries

- Building and Construction: Finely ground limestone powder acts as a filler in cement and concrete. It helps to improves durability.

- Textile Industry: Limestone powder is used as an environmentally friendly filler to add volume and weight in certain textiles like carpet and vinyl, to improve colorfastness, and add resistance to textiles.

- Paint Industry: Limestone filler improves coverage, enhances durability, and reduces production costs.

- Glass Industry: Limestone powder is used as flux in glass manufacturing to improve chemical resistance and durability. It can also reduce melting temperatures.

- Plastic Industry: Limestone filler can improve impact resistance, elasticity, and heat resistance to ensure consistent performance across the entire product.

Choosing the Right Wet Grinding Solution

Economy Ball Mill can create custom ball mills to meet your specific needs—no matter your grinding style or industry. Factors to consider when selecting a wet ball mill include:

- Required particle size and distribution.

- Production capacity.

- Energy requirements.

- Maintenance needs.

Our expert team can help you determine the ideal grinding solution for your limestone processing needs, ensuring the optimal performance of your ball mill and the product quality of your end result. We even offer product development and testing services to help you get your process in order.

Achieve Limestone Size Reduction with a Custom Ball Mill

Wet ball mill grinding is an efficient and effective method for achieving the ideal limestone particle size for various industrial applications. Leverage our expertise at Economy Ball Mill and discover how we can help you customize your next ball mill grinding solution.

Whether you are a material processor or manufacturer, you can produce high-quality materials that meets the exacting standards of the building and construction, textile, paint, paper, rubber, glass, and plastic industries when you invest in the right grinding technology today.

Contact us online or call (606) 798-5724 to learn more about Economy Ball Mill and our custom ball mills. We are located in Tollesboro, Kentucky and serve clients across the USA, Canada, the UK, and worldwide with standard size or a custom-built ball mill units.