Ball Mills Can Process Pumice as an Alternative to Fly Ash

The construction industry is undergoing significant shifts as fly ash—a byproduct of coal combustion and processing—become harder to source with a national decline in coal manufacturing due to environmental regulations and the push toward renewable energy.

At Economy Ball Mill, we understand how manufacturers and concrete producers are seeking sustainable alternatives to maintain strength and durability in their mixes. One promising substitute is pumice, a lightweight rock known for its pozzolanic properties due to its high silica content and porous structure. Like fly ash, pumice reacts to form additional calcium silicate hydrate (C-S-H) and bind concrete, improving workability and long-term material strength.

Like fly ash, processing pumice into a consistent powder requires specialized ball milling equipment to ensure optimal performance in concrete applications.

Why Pumice is a Viable Alternative to Fly Ash

- Natural and abundant: Pumice is a naturally occurring volcanic stone, easing dependency on industrial byproducts.

- Pozzolanic properties: Enhances concrete strength and durability, similar to fly ash.

- Lightweight: The lightweight nature of pumice stone reduces the overall weight of concrete without compromising integrity.

- Eco-friendly: Unlike fly ash, pumice does not rely on coal production, aligning with a more sustainable construction practice—important for many end users.

How Grinding Mills Adapt to Process Pumice Efficiently

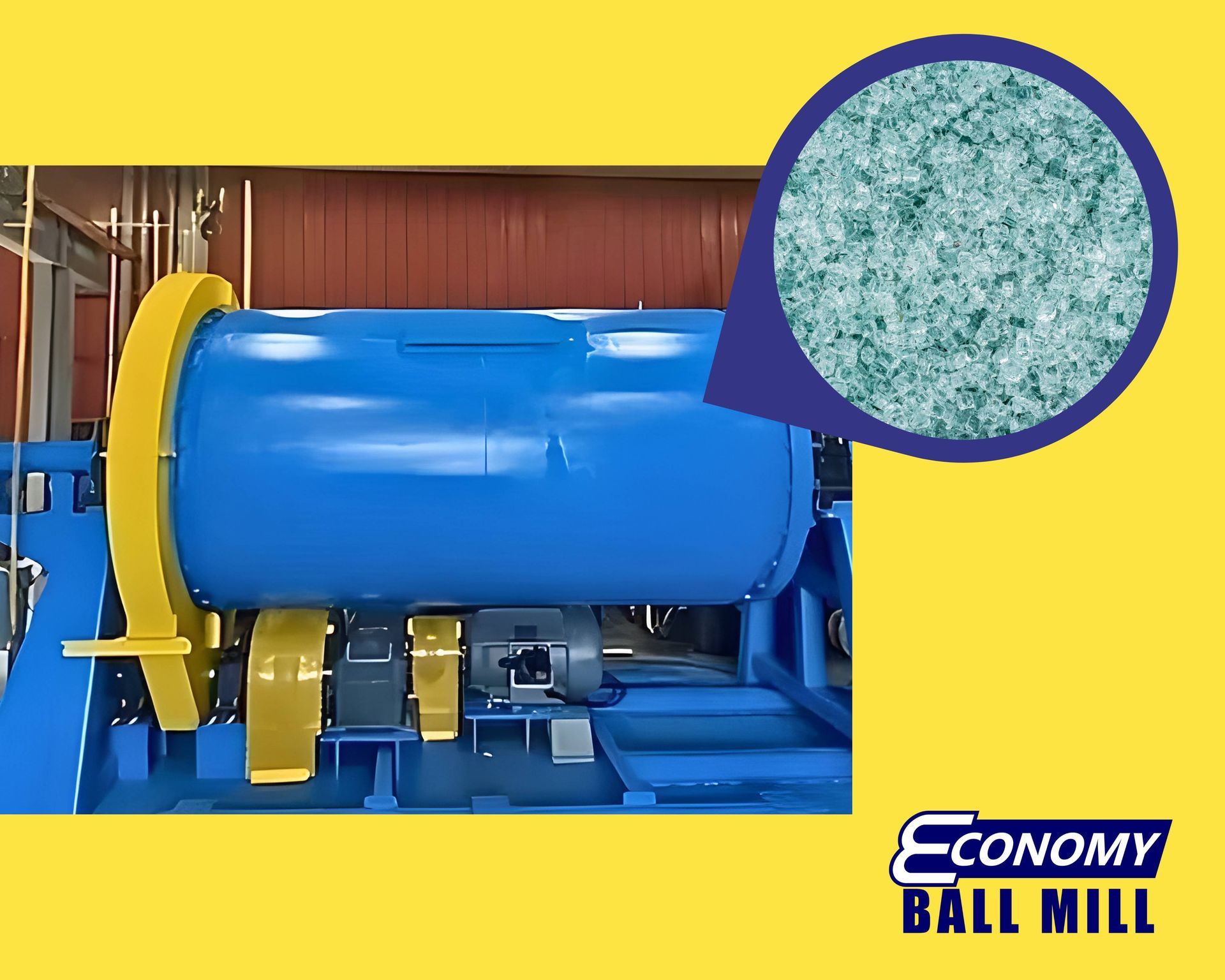

To integrate pumice into concrete mixes effectively, it must be ground into a fine, uniform powder. At Economy Ball Mill, we offer custom ball mills for grinding. Here’s how custom ball milling solutions can optimize pumice processing:

You can set your own adjustable grinding parameters to vary depending on different pumice sources with varying hardness. Our customizable ball mills allow you to adjust:

- Rotational speed.

- Grinding media size & material to prevent contamination.

You can better control dust and moisture with a custom ball mill.

- Pumice can be dusty when dry. Closed-circuit ball mills with integrated air classifiers help control particle size distribution and reduce airborne dust.

- For wet grinding applications, ball mills can be designed to handle slurry-based processing.

Whether for small-scale R&D or large commercial production, Economy Ball Mill can tailor custom ball mills to meet your demands.

Why Choose Economy Ball Mill for Pumice Processing?

With fly ash becoming less accessible, pumice presents a sustainable and effective alternative for concrete production. However, proper processing is key—ball mills play a crucial role in transforming raw pumice into a high-quality concrete additive.

At Economy Ball Mill, we specialize in designing and manufacturing high-performance ball milling systems that adapt to evolving industry needs. As concrete producers transition from fly ash to alternatives like pumice, our custom solutions ensure efficient, consistent, and cost-effective grinding for superior material performance.

Economy Ball Mill is committed to helping industries adapt by providing custom ball milling equipment for your pumice grinding process! We serve clients from around the world at from our location in Tollesboro, Kentucky. Contact us online or give call us at (606) 798-5724 to receive expert advice. A member of our team is standing by to discuss your ball milling requirements!