What is Pulverization and Why Will Ball Mills Help?

Whether you’re in the limestone mining and processing industry, a manufacturer of cosmetics or pharmaceuticals, or in any industry that requires reducing materials to finer particles, having the right equipment for particle size reduction is crucial. This process, known as pulverization, plays a vital role in many industrial or commercial manufacturing and production processes.

At Economy Ball Mill, we specialize in providing custom ball mill solutions to businesses worldwide from our central location in Tollesboro, Kentucky. In this blog post, we'll explore the concept of pulverization and how ball mills can help achieve the perfect particle size for your needs.

What is Pulverization?

Pulverization is the process of reducing solid materials into fine particles or powder. This technique is used across various industries for different purposes:

- To extract valuable minerals from ore

- To grind clinker and other raw materials like fly ash from coal processing and limestone powder for use in concrete and other construction goods.

- To create fine powder for medications, cosmetics, and more

- To prepare raw materials for various chemical reactions

- To process gemstones and precious metals

The goal of pulverization is to increase the surface area of various materials, which can enhance their reactivity, improve mixing properties, or facilitate further processing and manufactory. Achieving the desired particle size is crucial for many applications, as it can significantly impact the quality and efficiency of the final product.

How Does a Ball Mill Work?

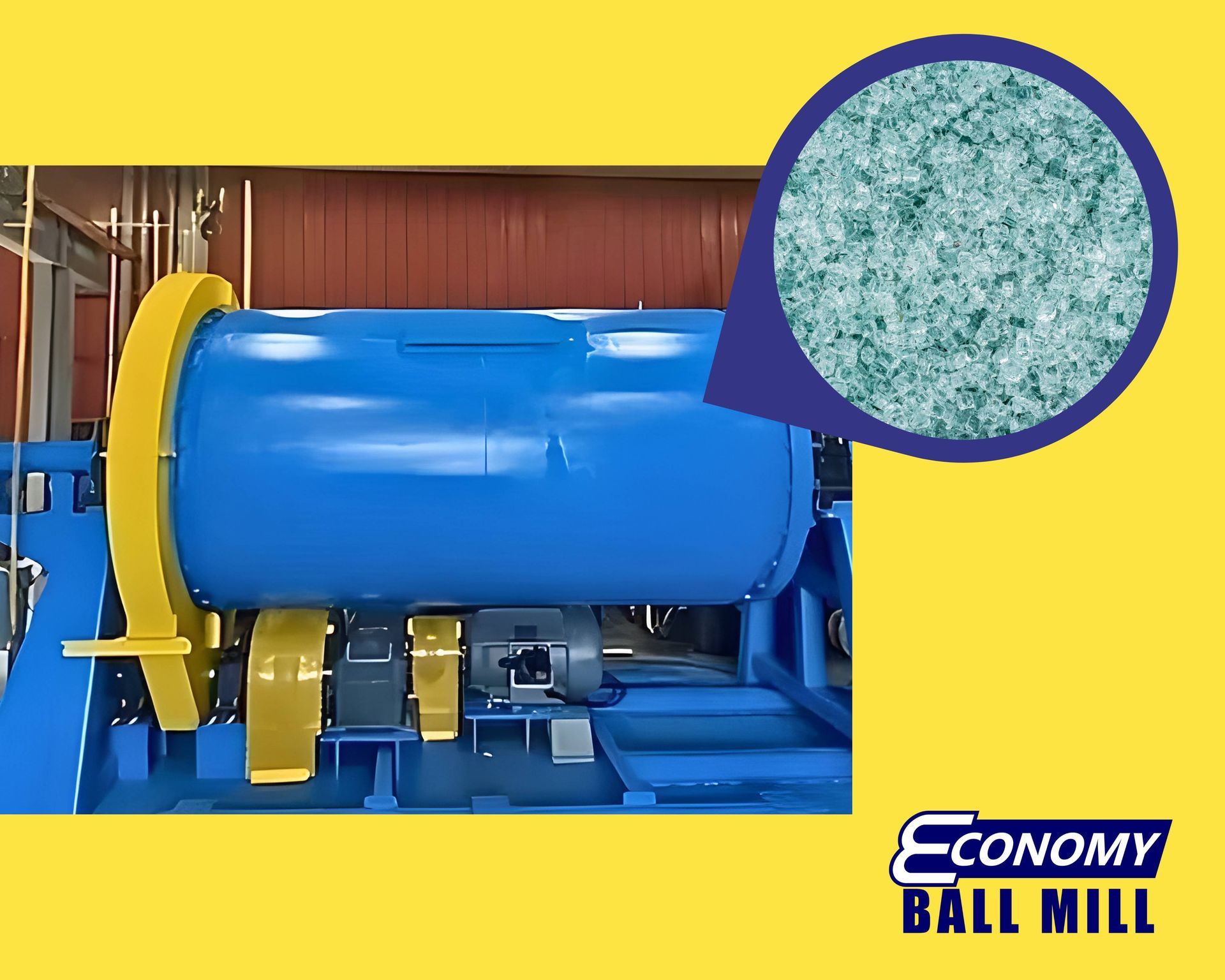

A ball mill is one of the most effective tools for pulverization. At Economy Ball Mill, we design and manufacture custom ball mills to meet the specific needs of our clients. Here's how a ball mill works:

- Structure: A ball mill consists of a cylindrical shell that rotates around a horizontal axis. The shell is partially filled with grinding media, typically steel balls or ceramic balls.

- Material loading: The material to be pulverized is loaded into the mill along with the grinding media.

- Rotation: As the cylinder rotates, the grinding media and material are lifted up the sides of the cylinder and then fall back down, creating a cascading effect.

- Grinding action: The falling balls collide with each other and with the material, crushing and grinding it into smaller particles.

- Continuous operation: The process continues until the desired particle size is achieved. Some ball mills operate in a continuous flow, where material is constantly fed in and discharged.

- Customization: At Economy Ball Mill, we create custom ball mills in different sizes, rotational speeds, and with different interiors and grinding media to achieve specific particle sizes and throughput rates.

Ball mills are highly efficient for pulverization because they can achieve very fine particle sizes, operate continuously, and handle a wide range of materials. They're also relatively low-maintenance and can be designed for wet or dry grinding processes.

Let Us Customize A Ball Mill Solution for You

At Economy Ball Mill, we understand that each industry and application has unique requirements. That's why we work closely with our clients to design and manufacture ball mills that meet their specific needs, ensuring optimal performance and efficiency in their pulverization processes.

Contact us online or call (606) 798-5724 to learn more about how a custom ball mill solution from Economy Ball Mill can help you achieve your pulverization goals efficiently and effectively.

We serve clients around the world from our site in Tollesboro, Kentucky and look forward to working with you, whether you're in the mining industry, pharmaceutical manufacturing, or any other field that requires precise particle size reduction.