Best Grinding Machine for Ceramic & Glass Frit

For manufacturers of products that contain ceramics and glass like makers of decorative tiles, specialty glass, and manufacturers of ceramic or glass coatings, frit plays a vital role in countless applications.

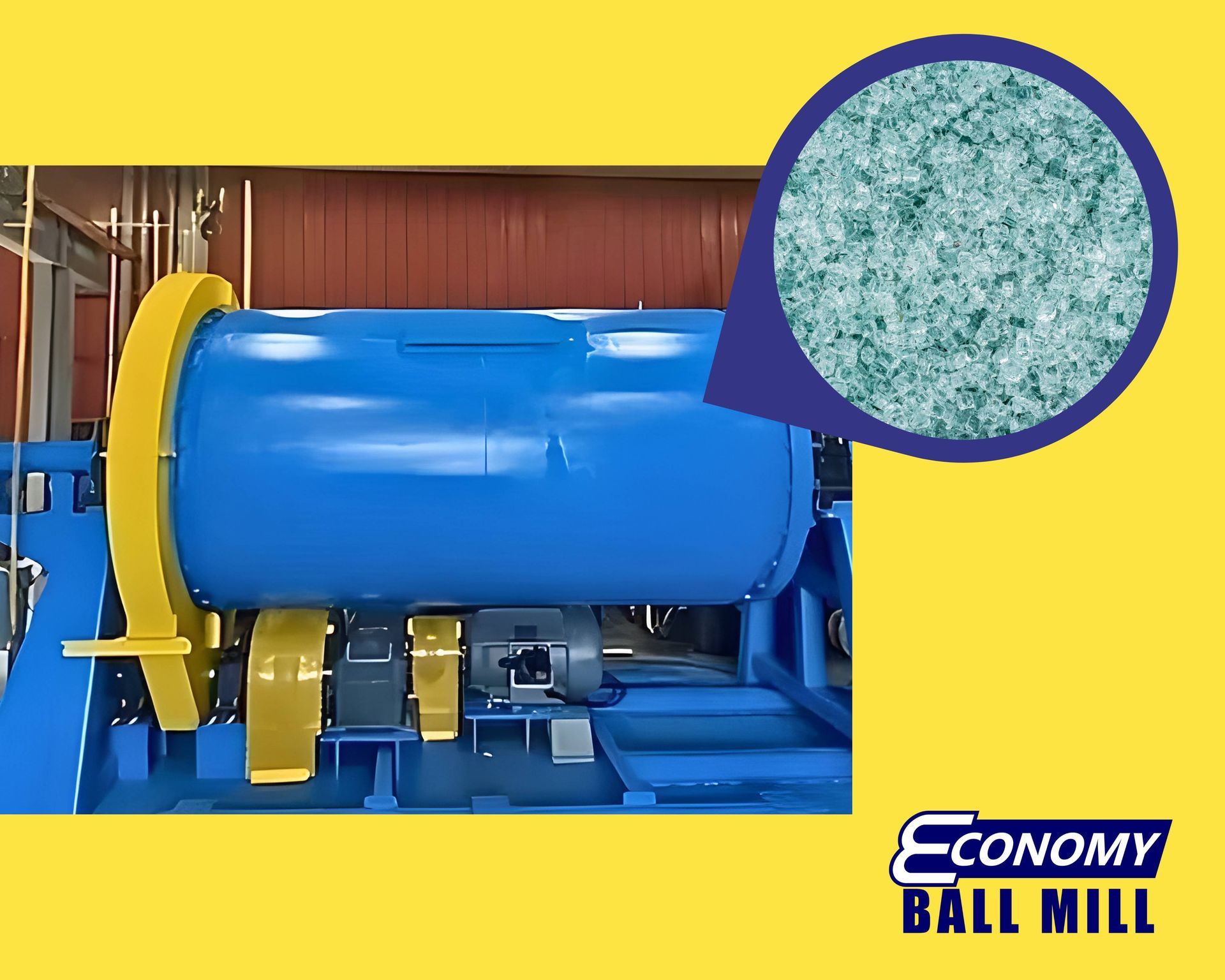

At Economy Ball Mill, we engineer custom ball mills—grinding machines for ceramic and glass frit—to help manufacturers achieve precise particle size control, consistent texture, and reliable batch-to-batch performance in their frit and coatings. Our ball milling systems are built for the toughest materials. Learn how we can become a part of your manufacturing process.

What Is a Frit?

Frit is a fused mixture of raw materials—typically silica and other oxides. Frit is melted, cooled, and then ground into a fine powder. This powder becomes the foundation for ceramic glazes, glass coatings, and enamels used across multiple industries.

The grinding stage is where solidified frit pieces are processed into a uniform powder ready for precise applications.

Why Ball Mills Excel for Frit Glass Processing

When processing frit for ceramics and glass, consistency is everything. A custom ball mill from Economy Ball Mill provides unmatched control over the size and distribution of your ground material.

Here’s why ball mills outperform other types of grinding equipment for frit applications:

- Controlled Impact & Attrition: The rotating cylinder and grinding media apply both impact and shear, ensuring even reduction without overgrinding fragile particles.

- Reduced Contamination: Our mills can be lined and fitted with stainless steel or ceramic media, maintaining product purity—critical for glass and ceramic manufacturing.

- Customizable Fineness: Adjust rotational speed, media size, and residence time to achieve your target frit particle sizes for glazes, enamels, or powder coatings.

- Energy Efficiency: Designed to minimize energy loss, Economy Ball Mill systems help lower total operational costs while maintaining superior output quality.

Ceramic and Glass Frit Applications

Ceramic and glass frit are integral to the performance and appearance of industrial or commercial applications. From kitchenware and bathroom tiles to advanced electronics and architectural glass, Economy Ball Mill can help you find the perfect grind for a diverse number of frit formulations and uses, including:

- Ceramics & Tile: Frit creates smooth, glossy glazes and enhance surface durability and color.

- Glass Manufacturing: Ground frit powders serve as fluxes or for bonding, helping lower melting points and add color or function to decorative and structural glass or ceramics.

- Industrial Enamels: Used in protective coatings that need thermal and chemical resistance.

No matter the end use, manufacturers need frit of a consistent grind. With a custom-engineered ball mill from Economy Ball Mill, manufacturers achieve the repeatable precision needed for reliable performance in any frit application.

Custom Ball Mills for Precision Frit Grinding

Economy Ball Mill’s custom ball mills are engineered for durability, accuracy, and efficiency. Every system is built in the USA from corrosion-resistant materials to handle abrasive or high-purity frit blends.

Our team offers full in-house testing and modeling to help determine your ideal process before production begins. Key advantages include:

- Custom Sizes: From small R&D test mills (20" x 28") to large production systems.

- Material Flexibility: Stainless steel, ceramic-lined, or rubber-lined interiors & grinding media.

- Scalable Design: Perfect for lab trials, pilot lines, or full-scale production.

- Testing Services: Bring or ship your material for modeling and

validation of process or cycle time in our Tollesboro, Kentucky facility.

Our team partners with you to configure the ideal grinding solution optimized for efficiency, energy savings, and quality assurance.

Partner with Economy Ball Mill for Glass and Ceramic Grinding

Whether you’re manufacturing industrial or consumer products, ceramic glazes, paint, glasswork, or high-performance enamels, the right grinding technology can improve your bottom line. Economy Ball Mill builds the best custom ball mills, which you can use for ceramic and glass frit applications.

We proudly serve clients across the USA, Canada, and worldwide from our facility in Tollesboro, Kentucky—helping every customer achieve the perfect grind. Contact us online or call (606) 798-5724 to learn more about our custom-engineered ball mills, product development testing, and full-scale production support.