Stainless Steel Grinding Balls for Contamination Control

In many grinding applications, minor wear is a regular part of the process. But in industries where ingredient purity is vital—like precious metals, pharmaceuticals, and ingredient processing—contamination is a real constraint that can determine whether a batch passes and whether a process is scalable.

That’s why contamination control in ball milling should be treated carefully. The grinding media and your ball mill’s liners both contribute to what ends up in the final product.

Grinding Media and Contamination Control

When people talk about contamination from particle size reduction, they’re usually talking about one of two mechanisms: wear and corrosion.

Wear is straightforward—when objects of varying levels of hardness contact, this kinetic energy gradually removes material from the media and internal surfaces ball-to-ball, ball-to-liner, and ball-to-material.

Corrosion is more subtle, but in wet grinding, corrosion can an important factor. Elements like pH and temperature can change how quickly a material breaks down, and corrosion can accelerate wear in ways that don’t show up until you track impurity levels over time.

This is also why dry vs. wet grinding matters for purity-sensitive products. Wet systems often can introduce corrosion-related effects that change your material profile.

Stainless Steel Grinding Balls and Liners Can Help

Stainless steel is often chosen for contamination control because it can reduce corrosion-driven issues compared to carbon steel, especially in wet environments or when the material being milled is reactive. That doesn’t mean stainless eliminates contamination—any media will wear—but it can provide a more stable and predictable performance in applications where rusting, discoloration, or accelerated breakdown is unacceptable.

Where teams get the best results is when stainless media selection is paired with an intentional approach to the mill interior.

A mill can be built so that the surfaces most likely to contribute contamination are protected with liners designed to control wear and reduce direct metal contact.

This matters because it’s common to see a grinding media choice paired with an interior that still sheds material. If purity is the goal, the media and the mill liner should agree with each other.

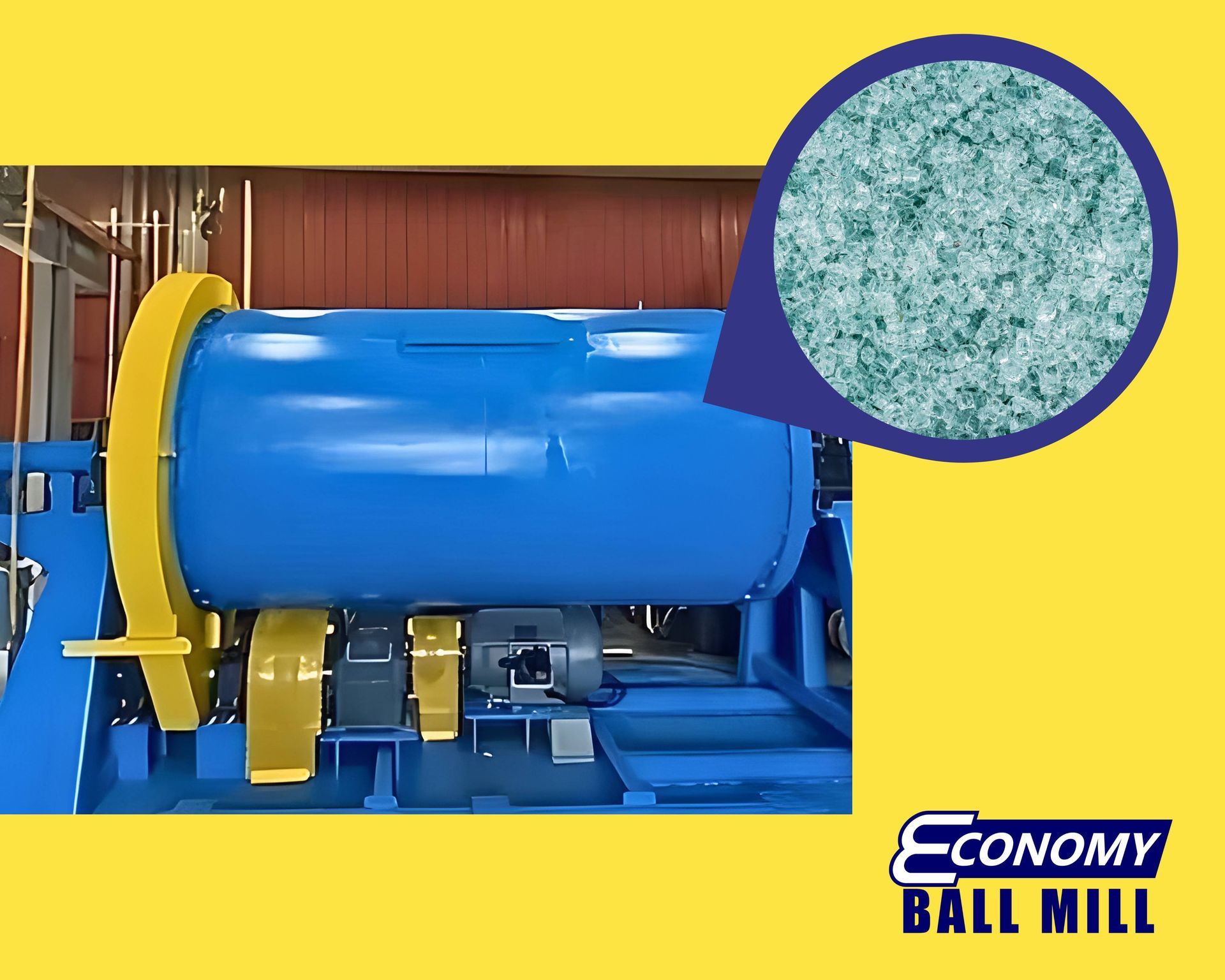

Economy Ball Mill can create stainless steel lined ball mills that can be configured so the media, liners, and internal components work together to protect product purity without sacrificing the fundamentals—throughput, particle size targets, and durability.

When to Choose Steel Grinding Balls Instead of Ceramic

The right grinding media choice depends on what contamination is unacceptable, what kind of grinding energy the process needs, and how the material behaves under impact.

- Stainless steel balls are often the right call when you need the density and durability of steel media, but you can’t tolerate the corrosion behavior—or the variability—that sometimes comes with carbon steel in wet or sensitive environments.

- Ceramic media is often selected when metallic pickup needs to be minimized as much as possible. Ceramic wear signatures can still matter depending on the product, and the process has to be compatible with the media’s behavior under impact and run conditions.

- Carbon steel balls still make sense—particularly in less reactive conditions or where pickup isn’t a problem.

If you’re trying to solve contamination problems and you only change the balls, you may only solve part of the problem. The better question is whether you need stainless media alone, a lined environment, or a combination.

In precious metals processing, contamination can affect consistency and chemistry. Stainless media and controlled interior surfaces are often used when teams are trying to stabilize that variable. In other environments, the concern is usually repeatability and cleanliness across batches.

A mill that’s designed with consistent wear behavior in mind tends to outperform generic configurations over time.

Let Us Customize Your Milling Equipment Around Your Processes

At Economy Ball Mill, we offer custom ball mills and industrial solutions are custom-made with integrity. We can help you decide what grinding media and liners are right for your next ball mill—and our research and development process or toll milling services can help you make the best choice for your business.

Contact us online or call (606) 798-5724 to schedule a meeting to discuss your pulverization solution today. Based out of Tollesboro, KY, we serve clients worldwide and across the US.