Powder and Bulk Solids Challenges in Ball Milling

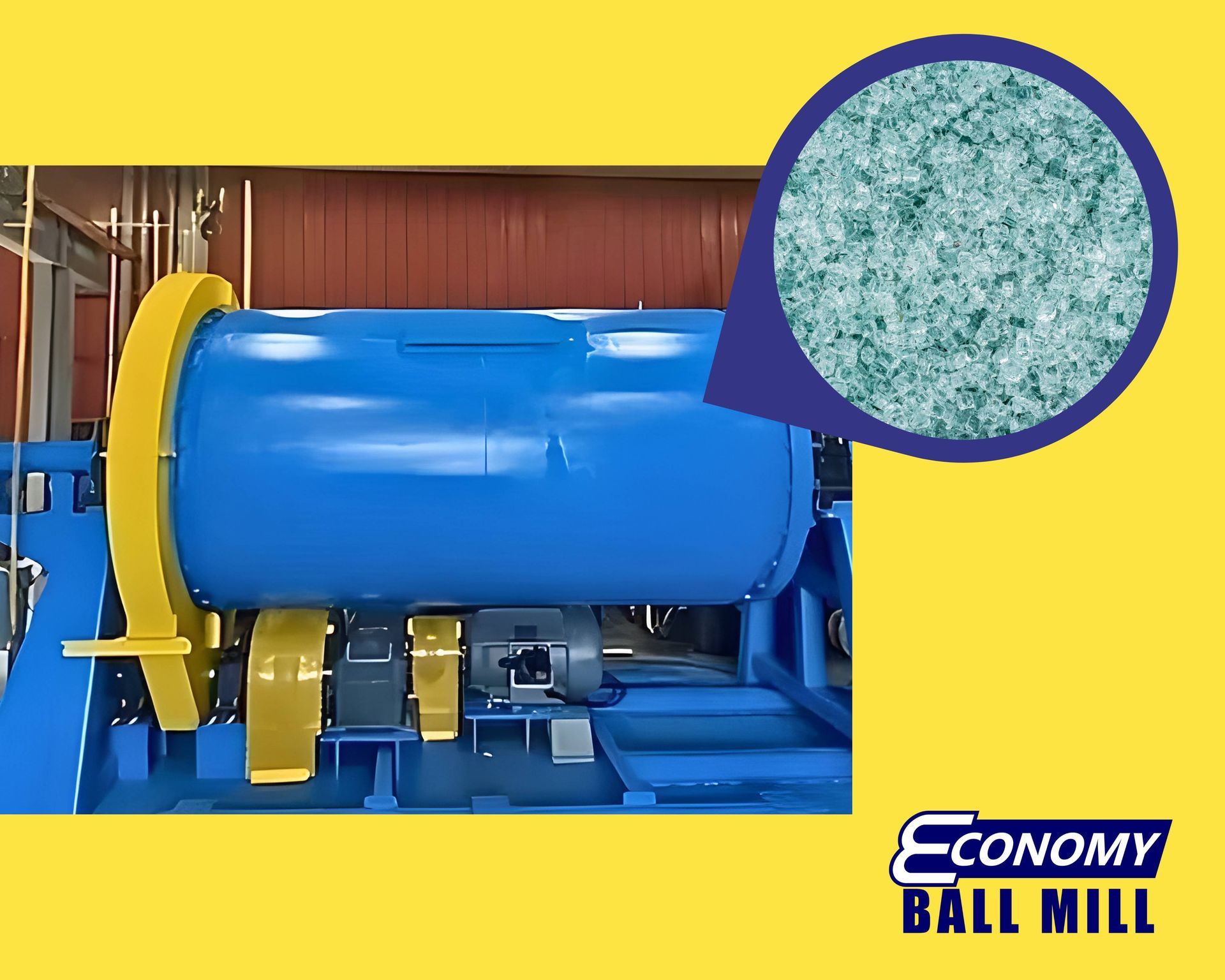

For manufacturers working in bulk solids processing, ball mills are often the heart of size reduction and material conditioning. But performance doesn’t depend on the mill alone. It depends on how well the system is designed to manage material behavior at critical transition points—most notably at the inlet and discharge.

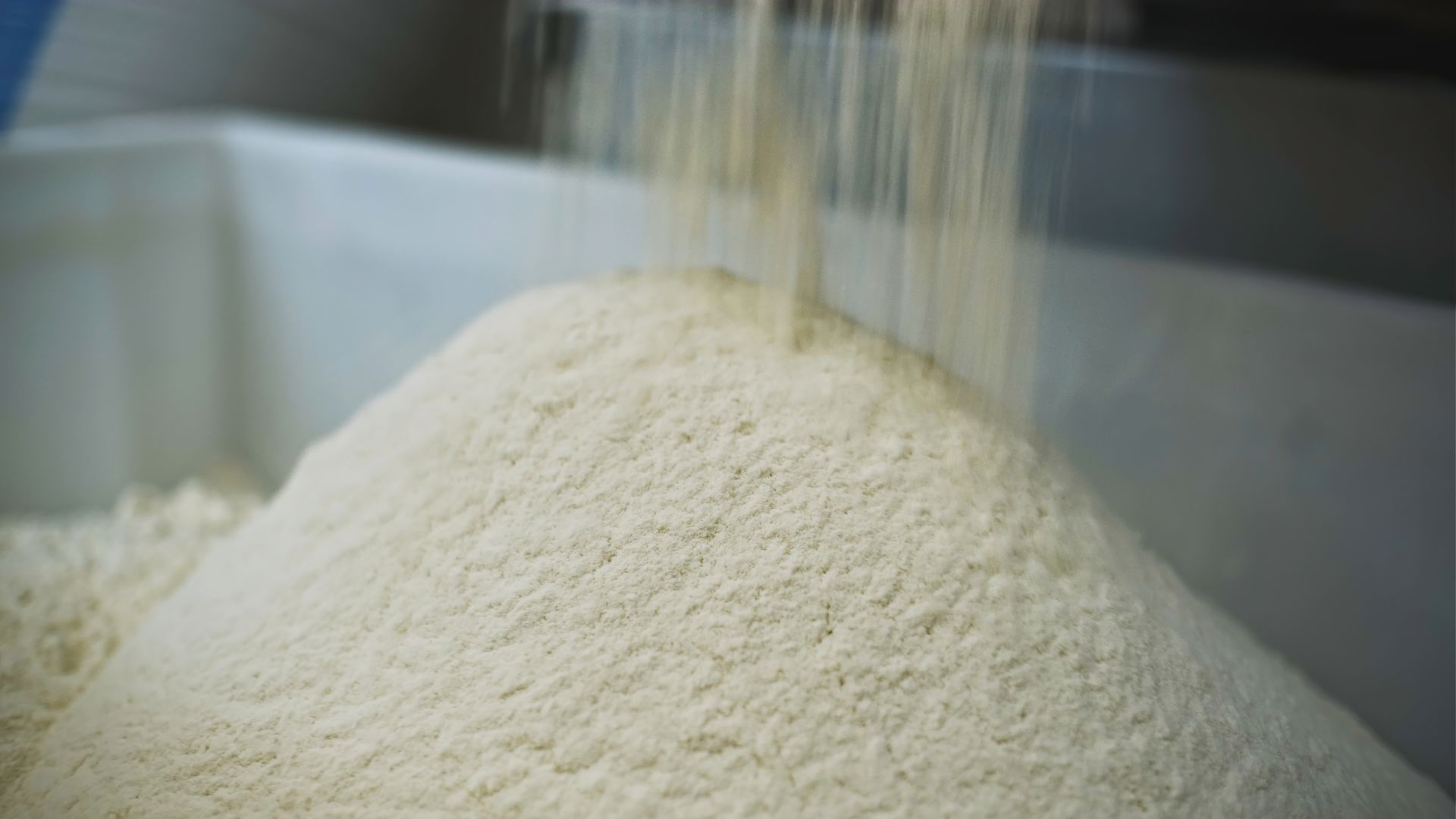

Handling bulk solids and powders is rarely straightforward—especially once materials enter a ball milling environment. Differences in particle size, moisture content, bulk density, and flow behavior can introduce challenges that affect throughput, consistency, and downstream processing.

Our experts at Economy Ball Mill are here to break down common issues seen in bulk powder and solid material applications—and how thoughtful mill design, liners, and support systems help resolve them.

Bulk Solids Processing Starts Before the First Rotation

In many industries, bulk solids processing issues show up long before grinding begins. Feeding inconsistencies can limit mill efficiency just as much as media selection or rotational speed. Common inlet challenges include:

- Uneven segregation of mixed particle sizes during transfer.

- Inconsistent feed rates due to poor flow characteristics.

From a ball milling standpoint, uneven feed introduces variability in residence time and grinding efficiency. Over time, this can affect particle size distribution, wear patterns, and energy consumption.

Best practices emphasize designing your equipment around material behavior—not forcing materials to behave in any certain way. That’s why Economy Ball Mill works with clients early in the design process to understand how their materials behave before they ever reach the mill—then we can engineer configurations, grinding media, and liners accordingly.

Instead, we apply procedural, experience-based manufacturing methods that combine:

- Collaboration with client process knowledge

- In-house product development and testing

- Custom liner and media selection

- Feed and discharge configuration design.

How Powder Bulk and Solids Flow Inside the Mill

Once material enters the mill, internal flow becomes the next critical variable. Bulk materials like solids and powders behave differently during the particle reduction process, under impact and shear, and in dry or wet grinding environments.

Material buildup is often about how internal surfaces interact with the material under rotation. Some of the most common internal challenges include:

- Material buildup.

- Poor cascading behavior.

- Uneven segregation between finer and coarser materials.

- Excessive dust generation

Industry guidance often highlights the importance of balancing impact and attrition forces. In practice, this balance is influenced by liner geometry, media selection, and mill speed—but also by how freely material can move through the grinding zone.

Economy Ball Mill designs liners for controlled material movement. The goal is to support consistent circulation, minimize dead zones, and prevent material from compacting where it shouldn’t.

Discharge Design

Discharge is one of the most underestimated areas of bulk solids processing. Discharge control is often a big topic of discussion for overall process stability. Best practices focus on controlled exit paths that maintain separation between your grinding media and the finished material—with systems like air classifiers and other add-ons customized to the material and process.

For dusty or fine powders, designs can be paired with dust collection interfaces to support cleaner, safer operation.

Partnering Together for Better Outcomes

At Economy Ball Mill, partnering with our clients is central to how we work. Whether you’re refining an existing system or developing a new application for particle size reduction, our team brings the experience needed to support your process.

Contact us online or call (606) 798-5724 to schedule a meeting to discuss your ball milling needs with a member of our team. Based out of Tollesboro, KY, we serve clients worldwide and across the US.

Looking for a third-party partner who can grind your material on-site? Learn more about our toll grinding services!