Optimize Cycle Time in Ball Milling with Precise Testing Services

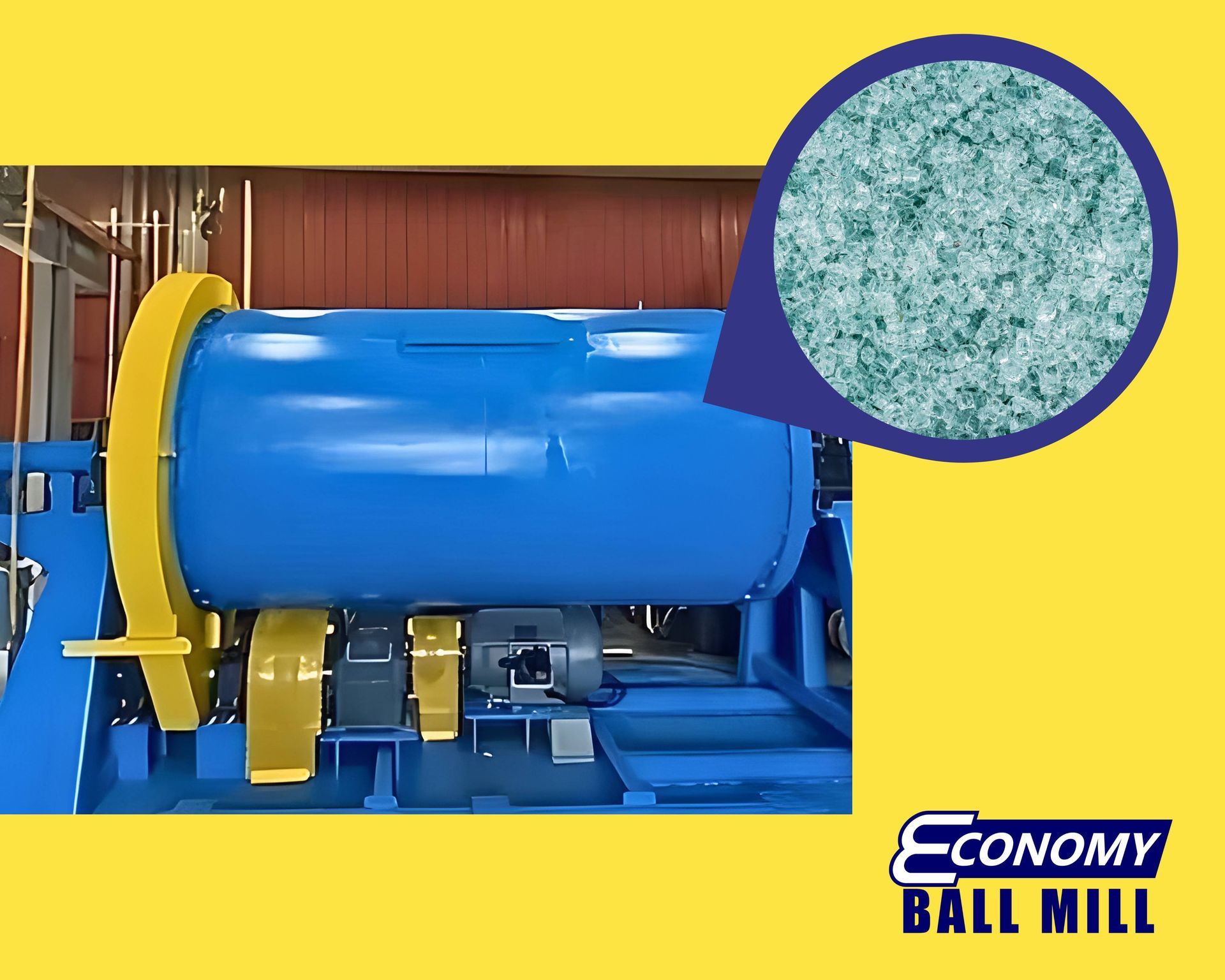

At Economy Ball Mill, build custom ball mills we engineer for efficiency. Your grinding system can consume a large percentage of your processing energy, so we understand how vital it is to optimize your cycle time formula.

Thoughtful grinding systems help slash costs and maintain quality. But when it comes to manufacturing, guesswork isn’t an option. That’s why we offer Ball Mill Development & Testing services to help you eliminate trial-and-error before your order. This systematic approach to custom ball mill design is one way that we take control over data-driven solutions to transform your grinding efficiency.

Your Cycle Time Optimization Starts in Our Facility

Our in-house testing bridges the gap between theory and when the grinding process begins on your factory floor:

- Predictive Modeling: Replicate full-scale production in our 20"x28" tester ball mill using just 10 gallons of your material.

- Real-World Testing: Test dry/wet grinding, residence times, and particle size distributions (PSD) under your process conditions.

- Scale with Confidence: Upscale batches 6x larger (at $4–$5/lb.) to validate throughput and energy savings before commissioning your custom ball mill.

How To Calculate Cycle Time Formula

A universal formula for understanding cycle time is:

Total Cycle Time = Active Grinding + Load/Unload + Hold Time + Auxiliary/Idle Time.

- Loading/Unloading: This can take as much as 30% of your total processing time and can include bottlenecks like manual handling or conveyor speed.

- Active Milling: Time spent grinding, dictated by target particle size and material hardness. This can take the bulk of your energy use.

- Hold/Dwell Time: Critical for stability, material bonding, or cooling due to frictional heat.

- Auxiliary Tasks: Cleaning, adjustments, or other maintenance between batches.

- Idle Time: Machine downtime due to material delays or changeovers.

Your Roadmap to a Personal Cycle Time Formula

At Economy Ball Mill, we partner with you to slash cycle times and elevate efficiency:

- TEST: Ship us up to 10 gallons of material. We’ll model your grind to quantify an exact active grinding time for your target fineness.

- SCALE: Validate in larger mills ($4–$5/lb.) for full-process confidence.

- BUILD: We engineer a mill with liners/media attuned to your data.

- SUPPORT: Our Kentucky-based engineers keep your process optimized.

In weeks, we’ll help you optimize and trim your grinding time. Whether you need wet grinding for limestone dust control or dry process grinding for cosmetics or food processing, we simulate your exact conditions to eliminate guesswork. Start fast and rent a test mill to experiment without halting production.

Contact Us to Home in Your Manufacturing Cycle Time

Stop overpaying for trial-and-error processing or under-optimized production cycles. Our experts help your business eliminate guesswork in calculating manufacturing cycle time—transforming unpredictable variables into optimized, data-backed production workflows.

Partner with us to engineer a clear formula for your grinding process. Contact us online or call (606) 798-5724 to learn more about your next custom ball mill with in-house manufacturing as well as product development and testing services from Economy Ball Mill!

We serve clients around the world from our site in Tollesboro, Kentucky and look forward to working with you.