Custom Ball Mill Supplier for Cosmetics Brands

At Economy Ball Mill, our industrial ball mills supply a variety of manufacturing and materials-processing industries—from limestone, fly ash, pumice, and precious metals to ceramics, inks, and biologics. But did you know that the power of ball mills can extend into the world of fashion and cosmetics?

Many brands—from indie innovators to established leaders, strive to take command of their production process and keep every stage of their unique processes in-house. Micas, silicas, and other mineral and inorganic compounds are a key ingredient in the high-stakes and competitive world of cosmetics. The velvety texture of a luxury eyeshadow, the flawless coverage of a foundation, and the brilliant payoff of a pigment all hinge on the quality and consistency of their ingredients.

Our custom ball mill solutions are engineered to deliver the unmatched quality, efficiency, and agility your beauty business or cosmetics manufacturing company need to create market-leading products.

Ball Milling in Cosmetics for Uncompromising Quality

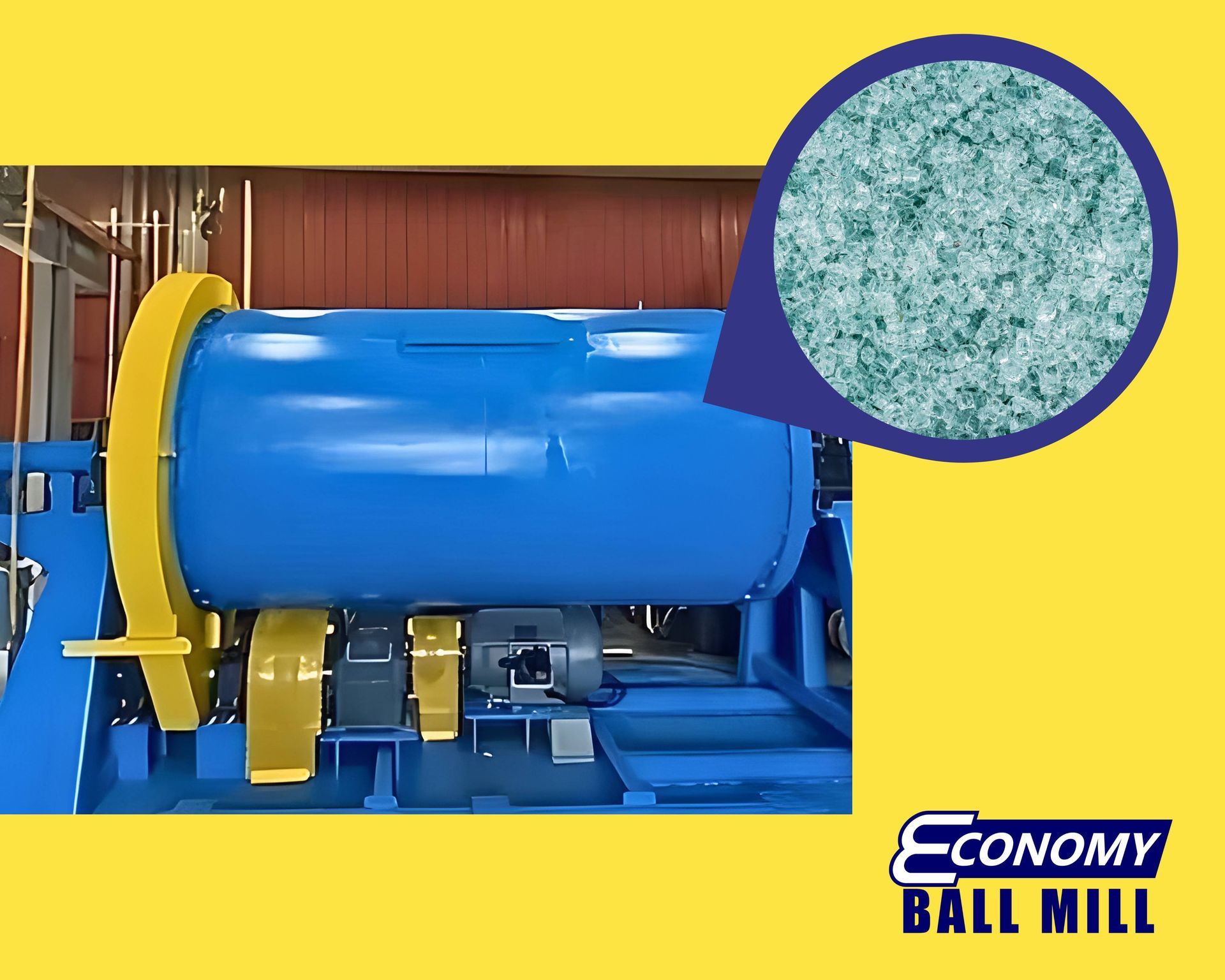

A ball mill is a refined grinding machine that uses impact and attrition from grinding media to reduce larger particles to a more even and precise level of fineness. For the cosmetics industry, this technology allows you to bring your ingredient sourcing in-house, enabling you to produce unique or superior products with improved consistency and transparency.

- Pigment & Oxide Grinding: Achieve brilliant color payoff and a smooth, blendable texture by reducing cosmetic pigments and oxides to a perfectly consistent, ultra-fine particle size.

- Foundation & Base Production: Create incredibly smooth foundations, pressed powders, and concealers by ensuring all components are milled to a uniform fineness that eliminates and unwanted texture or grittiness.

- Specialty Product Creation: Develop innovative products like shimmering highlighters, long-wear blushes, and eye-safe pigments by precisely controlling the ingredients and particle size distribution for optimal adherence and effect.

- Natural Ingredient Processing: Mill natural clays, micas, and other mineral-based ingredients to a fine, consistent powder that is ready for safe and effective use in your formulations with other pre-processed materials from other trusted partners.

Small Mill or Large Mill? We Got You Covered!

At Economy Ball Mill, we produce custom sizes from 20in x 10in to 6ft x 10ft so that you can process batches in-house, from R&D to full-scale production. We also offer an in-house testing lab so that you can scale your operations to ensure every batch of pigment, base, or additive meets your exact specifications for fineness and texture.

Quickly adapt your milling process for new product lines, limited editions, or custom formulations with a dedicated small mill. Go with a larger machine for more efficient processing.

Partner with our USA Ball Mill Manufacturer For Cosmetic-Grade Excellence

All our mills are constructed in America with corrosion-resistant, easy-to-clean stainless steel to ensure total product purity, making them ideal for cosmetics. By integrating a custom ball mill from Economy Ball Mill into your production line, you can revolutionize your cosmetics business from the inside out and gain control over your product finishes, protect your proprietary formulas, and build a brand known for its impeccable quality.

Our expertise is designing and manufacturing custom ball mills tailored to your specific production needs. Get our team on your order! Contact us online or call (606) 798-5724 to learn more! We serve clients around the world from our site in Tollesboro, Kentucky and look forward to working with you.