Outsource Your Ball Mill Production with Toll Grinding

When you’re a growing manufacturer or industrial provider, investing in a full ball milling system isn’t always realistic. Investment budgets are tight, floor space is limited, and you may still be working out your ideal production profile.

That’s where outsourced particle size reduction services become a smarter, lower-risk path forward.

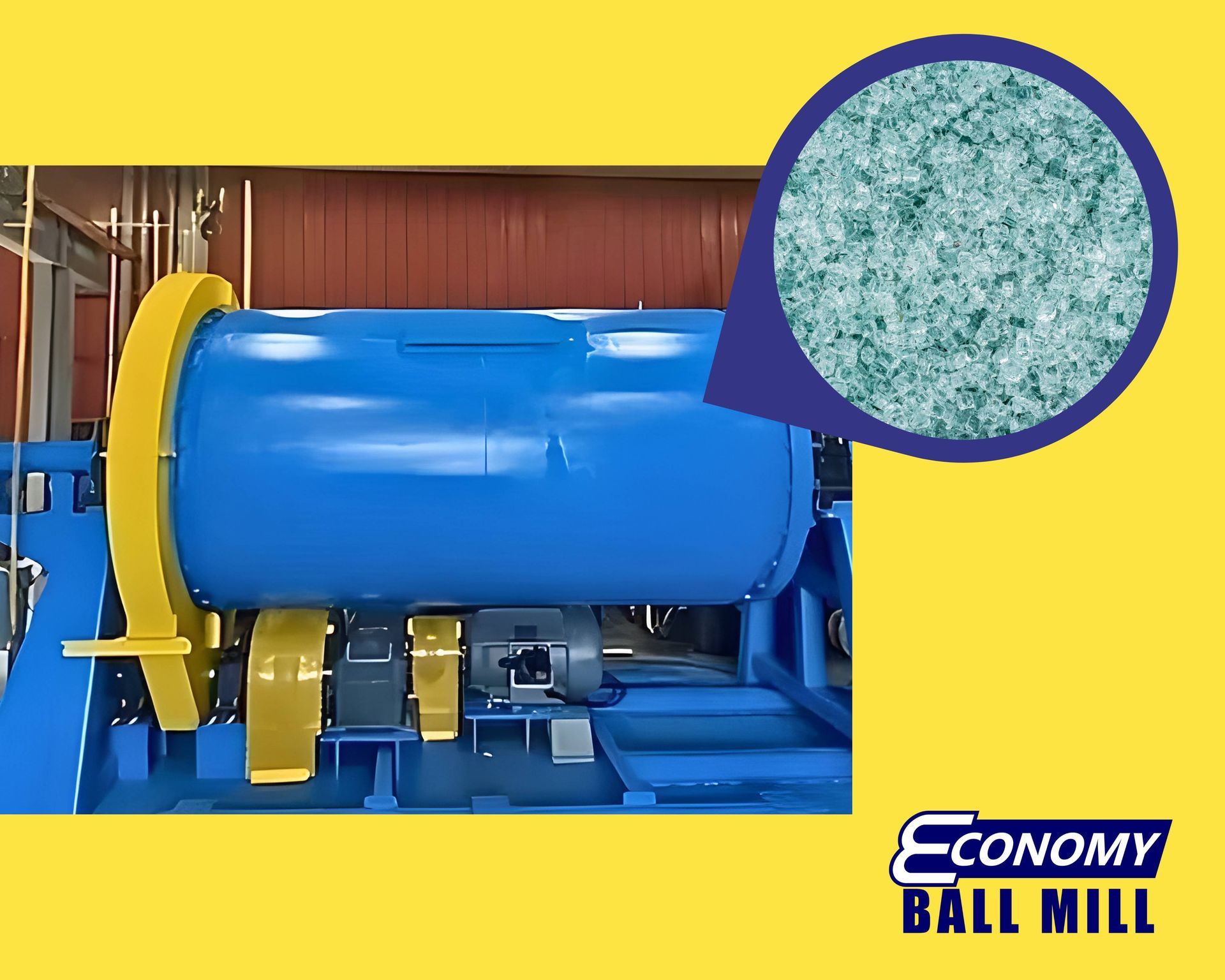

Instead of buying equipment before your process is proven, toll grinding lets you send your raw materials to Economy Ball Mill for refining. We custom manufacture ball milling equipment for clients around the world and can grind, test, and refine your material on our own ball mills—then send back finished product and data you can trust.

Later, when your volume and specifications are stable, we can design and build a custom ball mill that replicates those proven toll-milled results on your own production floor.

What Is Toll Grinding?

Toll grinding (also called toll milling or contract grinding) is a service model where you supply the raw material and a specialist provider like Economy Ball Mill supplies the ball mills, operators, and process expertise to grind that material to your target specification.

We adjust variables like residence time, grinding media size, and rotational speed until we hit your target particle size distribution (PSD). You receive finished product plus test data you can use for quality and scale-up.

- Predictable cycle times – so you can plan production, energy use, and labor with confidence.

- Repeatable wet or dry conditions – depending on whether your product behaves better in a slurry or as a dry powder.

Toll grinding is especially valuable when you:

- Need ball milling capability before you’re ready to own and maintain a mill.

- Want to validate a new product formula or material blend.

- Need extra capacity for a surge in demand.

It’s the “rent, don’t buy” option for particle size reduction.

What Are Particle Size Reduction Services?

When we talk about particle size reduction services, we’re talking about precise control of particle size distribution – not just an average size, but the full spread that affects flow, packing, strength, appearance, and downstream performance.

At Economy Ball Mill, our particle size reduction services start with a 20" × 28" test ball mill that can simulate full-scale conditions using as little as 10 gallons of your material.

Once we’ve confirmed a grind profile that works, we can scale batches up to six times larger so you can validate throughput and quality before committing to your own mill.

When Toll Grinding Makes More Sense Than Buying a Mill

Owning a ball mill gives you control—but only when your process and volume are ready for it. For many small and mid-sized manufacturers, toll grinding is the smarter first move in at least four scenarios.

- You’re Still Proving Out a New Product: If you’re developing a new powder, coating, filler, or compound, your milling needs will change as formulas evolve. Toll grinding lets you experiment with different particle sizes and distributions and adjust grinding media and liner types without buying hardware multiple times.

- Your Volume Is Intermittent or Seasonal: If your milling demand spikes a few times a year or you only grind certain materials periodically, a dedicated ball mill can sit idle for long stretches. Economy Ball Mill converts those irregular needs into a predictable toll grinding cost. You pay for capacity only when you actually use it.

When It’s Time to Bring Ball Milling In-House

There is a point where owning your own ball mill outperforms sending material out for toll grinding. Typically, that’s when your formulation and target PSD are stable and unlikely to change OR your production volume is high enough that toll fees outweigh equipment, energy, and labor spread over the year.

At that stage, Economy Ball Mill can take what we learned from your toll projects and build a custom mill that matches your proven process—rather than guessing at a system—because we already know your preferred grinding needs, expected cycle time range, and throughput.

Questions to Ask Before You Decide to Outsource or Buy

If you’re on the fence between toll grinding and buying a mill, a few quick questions can clarify your next step:

- Do we have stable, long-term volume, or is our demand still unpredictable?

- Do we know our target particle size distribution well enough to specify a permanent system?

- Can our current team support operation, maintenance, and optimization of a ball milling line?

- How much would it cost us—in time and capital—to run multiple experiments in-house versus using specialized particle size reduction services with dedicated test equipment?

If you’re still in the “learning and proving” phase, toll grinding will almost always give you better data and less risk.

Talk With Us About Toll Grinding and Your Next Mill

Whether you’re validating a new product, catching up with demand, or mapping the route from R&D to full production, toll grinding is often the most efficient way to get moving.

At Economy Ball Mill, we offer custom ball mills, toll milling, and more from our facility in Tollesboro, Kentucky. If you’re wondering whether to outsource ball mill production with toll grinding or invest in your own equipment, we can help you run the numbers and design a path that fits your business.

Contact us online or call 606-798-5724 to schedule a toll grinding project or discuss a long-term ball milling solution tailored to your operation.